| |

|

![]()

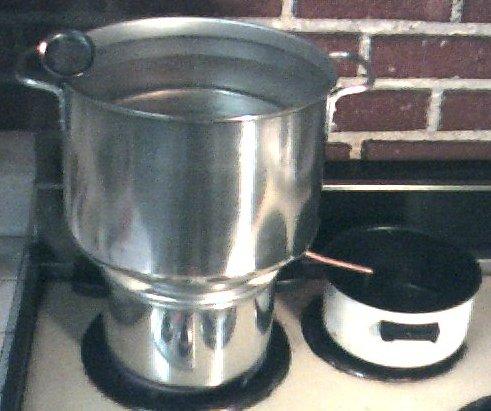

Using light weight aluminum pots this can be made to weigh only about 2 lbs 5 oz

for all three parts. A heaver more durable unit canbe made that weighs 4 lb 14

oz. The unit can be constructed with minimal labor out of commonly available

cheep pots and pans for around $20-$30. When in operation depending on the

heat source it produces about .9 oz/min or a glass of water every 10 Minutes

(1.25 cups/10 min). These instructions are also on a convenient Adobe file.

Using light weight aluminum pots this can be made to weigh only about 2 lbs 5 oz

for all three parts. A heaver more durable unit canbe made that weighs 4 lb 14

oz. The unit can be constructed with minimal labor out of commonly available

cheep pots and pans for around $20-$30. When in operation depending on the

heat source it produces about .9 oz/min or a glass of water every 10 Minutes

(1.25 cups/10 min). These instructions are also on a convenient Adobe file.

Designed for batch production, the water in the top and bottom pots will need to

be changed approximately every 40 min. This time would depend on the amount

of heat supplied to the bottom boiler pot. The water in the top cooling pot

increases about 30 degrees F for each 10 minutes and after 40 min is up to about

180 degrees F. One should end off when steam starts to come out around the

bottom of the top pot. This occurs around or above 180 degrees F. From start to

finish the water level in the bottom or boiler pot should have changed about 1.75”

depending on the size of the pot used. Don’t let the bottom run dry. Use an

output collection container that is marked to indicate when the boiler pot would

be low on water.

At end of the cycle after about 40 minutes if one uses some of the hot water from

the top to replace and refill the bottom water then one can get back into

operation in minimal time. At this rate one could produce a gallon on the average

of every 2.5 hours. This is taking into account the time for refilling with hot water

and heating back up to boil.

Offered by Mike.