| |

|

![]()

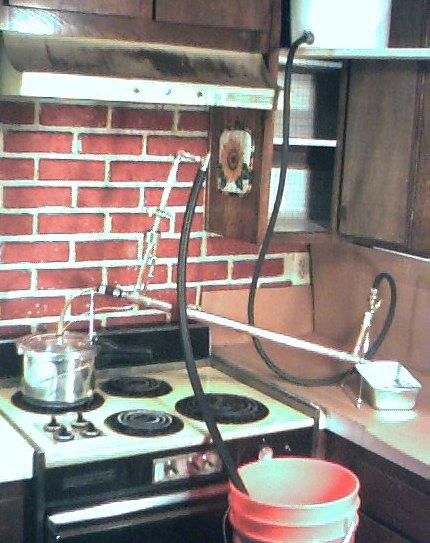

What about using continuous but controlled flow of cold water in a closed heat exchanger

to condense the steam? What about, in order to improve taste, evaporating the dissolved

hydrocarbons before introducing the water into the boiler? This approach is basically

building a water-cooled heat exchanger by using copper pipes and fittings. See the linked

test set up example at right. This approach also has incorporated lessons learned about

heating and evaporating the hydrocarbons in the incoming water to the boiler. Note by

dripping hot waste heat exchanger water into a small copper cup, it looses it hydrocarbons

into the air. An efficient heat exchanger can be made out of .5” and 1” copper pipe and

T-fittings for the end. Using the same electric stove producing 1750 watts and no insulation

on the hot spots, after one hour I measure 2.8 Gal of 140 deg F waste hot water and 6

cups of output distilled water at about 16 degrees above room temperature or 86 deg F in

my case. This is about 1.5 quarts/hr or 9 Gallons/day. More heat or more insulation and it

would produce more output water. More units or a bigger pressure cooker and several

heat exchangers running off the same pot in parallel would also produce more output.

What about using continuous but controlled flow of cold water in a closed heat exchanger

to condense the steam? What about, in order to improve taste, evaporating the dissolved

hydrocarbons before introducing the water into the boiler? This approach is basically

building a water-cooled heat exchanger by using copper pipes and fittings. See the linked

test set up example at right. This approach also has incorporated lessons learned about

heating and evaporating the hydrocarbons in the incoming water to the boiler. Note by

dripping hot waste heat exchanger water into a small copper cup, it looses it hydrocarbons

into the air. An efficient heat exchanger can be made out of .5” and 1” copper pipe and

T-fittings for the end. Using the same electric stove producing 1750 watts and no insulation

on the hot spots, after one hour I measure 2.8 Gal of 140 deg F waste hot water and 6

cups of output distilled water at about 16 degrees above room temperature or 86 deg F in

my case. This is about 1.5 quarts/hr or 9 Gallons/day. More heat or more insulation and it

would produce more output water. More units or a bigger pressure cooker and several

heat exchangers running off the same pot in parallel would also produce more output.

General Construction and Adjustment notes:

Be sure to remove the bur off the inside of the ¼” copper pipe that solders to the open-air-replenish-cup. With the small hole the inside bur leaves after pipe cutting it will sometimes cause the cup to overflow (depending on surface tension of the water at the time).

The saddle clamp needle valve was about 2.6 turns open for operation. The water valve to the bottom of the heat exchanger was open about 1/8 to ¼ turn. I used a typical stop valve that has a rubber washer in it. This changes dimensions while in operation depending on temperature. The result is a need to constantly adjust the flow rate. I would recommend using a ½”gate valve instead. This has no rubber parts and the flow once adjusted will not change with temperature. See below.

Rubber hoses works much better than vinyl but one cannot see though it. 5/8-inch car heater hose was used for sealing the ½ inch tubing (outside diameter) that was slipped into the ½ inch copper pipe (inside diameter) of the heat exchanger. This same hose was used for the output wastewater. I don’t recommend using hose on the output of the heat exchanger for the good distilled water. If one gets steam coming out (too little water flow in the exchanger) then the taste of the hose will get into the distilled output water.

The flow of cooling water in the heat exchanger can be adjusted by measuring how hot outside 1 inch pipe gets along it’s length. If one is careful one can use ones hand. Start at the cold end and gently move along the pipe to the point of needing to take ones hand off the unit. One wants to adjust the water flow so that it never gets hot at the cold end and is hot to no less than the center of the length. This is all depending on how much water you want to heat to what temperature. Generally one can do 130 to 180 degrees F for wastewater out of the heat exchanger without insulation.

Offered by Mike.